The selection of NC style considerably impacts the press brake’s performance, simplicity of use, and In general efficiency in sheet metal fabrication functions.

Comprehending the metal type is vital simply because Every metal has differing Actual physical properties. As an illustration, a superior carbon steel will frequently be less bendable by a press brake than lots of aluminum alloys due to the differences in ductility and energy.

This precision Command system allows operators to correctly posture and utilize power in the course of the bending method. The pedal generally delivers two-stage Procedure:

Advanced back gauge configurations, for example multi-finger or segmented models, supply enhanced balance and flexibility. These systems may be individually altered to accommodate advanced part profiles, guaranteeing steady assistance and referencing for an array of geometries.

The orientation and form of these grains is usually different for each product style and means of forming like forging, casting, and so on.

This is the commonest sheet bending strategy as it truly is made use of for most bending tasks. It employs an instrument generally known as the punch and v-die to bend sheet metals at sought after angles. Through the procedure, the bending punch presses over the sheet metal put about the V-die.

Simulation capabilities: Higher-stop systems can generate thorough 3D simulations in the bending sequence, making it possible for operators to validate courses prior to real generation.

A flange is really an edge that extends from the leading body of a sheet metal portion, commonly at ninety°. For those who have flanges in the look, consider the following dimensioning restrictions;

The again pressure assembly, created to be non-leaking According to the customer’s prerequisite, is made of a reversing seat valve industrial-grade press brake and two aid valves.

Picking out the suitable hydraulic press brake is usually challenging resulting from The range of possibilities readily available. Understanding the distinctions among NC and CNC styles is critical. This manual clarifies crucial…

The correct metal condition next a press brake Procedure is dependent on the dimensions and shape on the punches and dies. Dies and punches are typically created in such a way that they can be interchanged conveniently to support a wide array of Positions.

With this technique, all sides of the edge might be shaped at the same time, considerably boosting productivity. Moreover, the potential risk of surface area cracking from the deformed place is nominal.

TRUMPF BendGuide Uncover the possibilities of bending technology. Many elements is usually punched and fashioned in a very Innovative way with no getting time-consuming or highly-priced.

It is recommended to implement antiwear hydraulic oil ISO VG46# (with a median viscosity of 46mm2/s at 40°C). In the event the machine operates at temperatures under five°C for an extended interval, hydraulic oil ISO VG32# may be used.

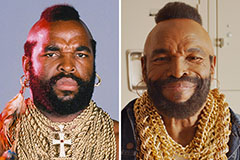

Mr. T Then & Now!

Mr. T Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!